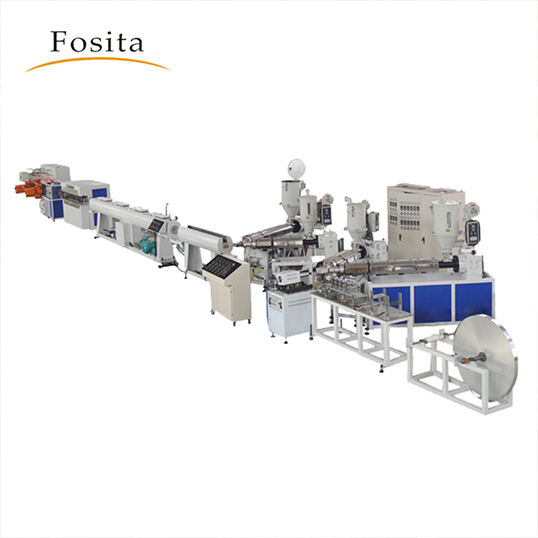

Fosita 16-32mm Multi Layers Overlap Welding Plastic-Aluminium-Plastic PEX Compound Pipe Production Line

| Place of Origin: | China |

| Brand Name: | FOSITA |

| Model Number: | FST-PAP Pipe |

| Certification: | CE ISD9001 |

| Minimum Order Quantity: | 1 set |

| Price: | USD60,000 |

| Packaging Details: | Film or wooden packaged |

| Delivery Time: | 30 days |

| Payment Terms: | T/T L/C |

| Supply Ability: | 5 sets per month |

- Overview

- Parameter

- Features

- Inquiry

- Related Products

Description:

Introduction of Pipe Line

Original creation aluminum pipe figuration system and exact aluminum pipe sitting system. That ensure welding to process welding line extended stability and aluminum pipe finished product frankly.

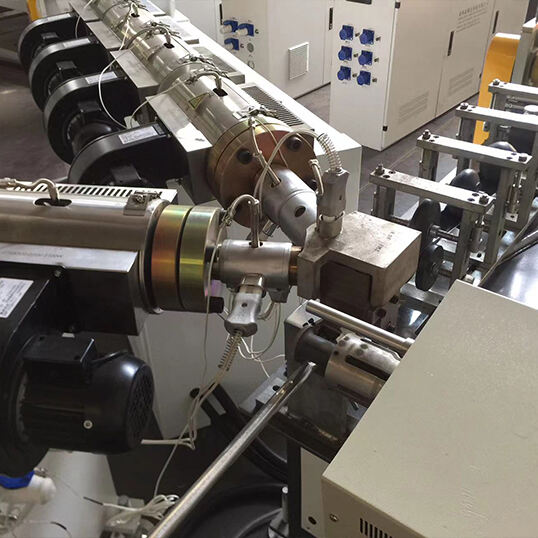

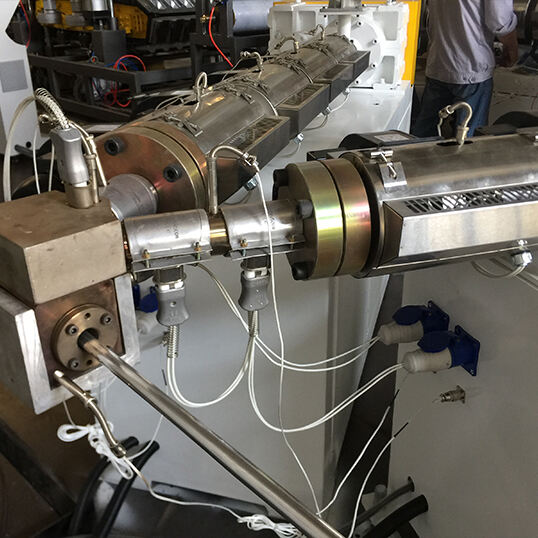

Co-extrusion die: Unique five layer co-extrusion technology ensures high and stable quality for alumimum plastic composite pipe. Advanced calibrating technology can develop the calibration quality. Ultrasonic welding machine with stable performance makes the flat weld seam and high quality.

Imported welding machine with TIG butt welding/ ultrasonic welder and roller type Al. tube ensure high productivity and perfect product in compliance with American standard. Al-tape jointing machine , layer after extrusion with two welding torches can easily guarantee die change and a long time continuous production in process with high quality product rate.

Aluminum strap auxiliary equipment: Special designed double station storage rack put the aluminum strap in advanced strap jointing machine, which ensures the aluminum strap quality. Aluminum storage unit makes the production continue, high performance forming table ensure good forming of plastic aluminum pipe.

Double station coiler: the automatic aligning device ensures the proper coiling position. Automatic loading saves time and labor. The tension adjusting function ensures coiling quality. Shifting device for station ensures the production continuing.

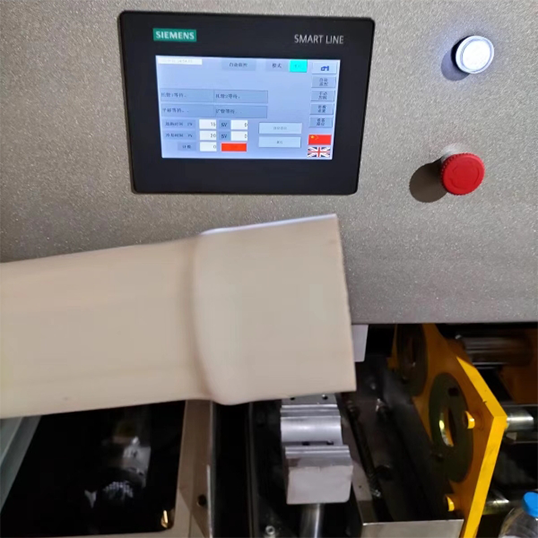

High automation: the whole line adopts advantage of computer controlling system which provides a well human-machine interface and gives an automatic cloosed-loop control to the extrusion, haul-off, temperature and the diameter of pipe.

Applications:

The aluminum plastic pipe has many advantages due to its special structure.

» No rusting

» Well resist burning

» Little heat-losing and good heating preservation

» Well enduring chemistry

» No deposit

» Resisting corrosion

» Long lifespan and easy to distort

» Strongly resisting ageing

Specifications:

| Pipe line model | Diameter Range(mm) | Max Output(KG/H) | Main Motor Power(KW) | Line Length(m) |

| FST-32 | 16-32 | 200 | 150 | 30 |

| FST-63 | 32-63 | 200 | 170 | 30 |

Competitive Advantage:

-

Specillay designed technique for stable and high quality extrusion

-

Good ultrasonic welding machine guarantee stable performance and perfect welding quality

-

Equipped with aluminium sheet feeding device to ensure continuous and stable production

-

Double winder with automatic winding displacement, tension control to achieve compact and nice coils of pipes

Tag:

Plastic Aluminium Pipe Making Machine, Plastic PEX PAP Compound Pipe Machine, Plastic-Aluminium-Plastic Compound Pipe Extrusion Line

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH