amashumi amabirha we-experience yokusetyenziswa komnyama we-plastic ngaphandle kwezilimi

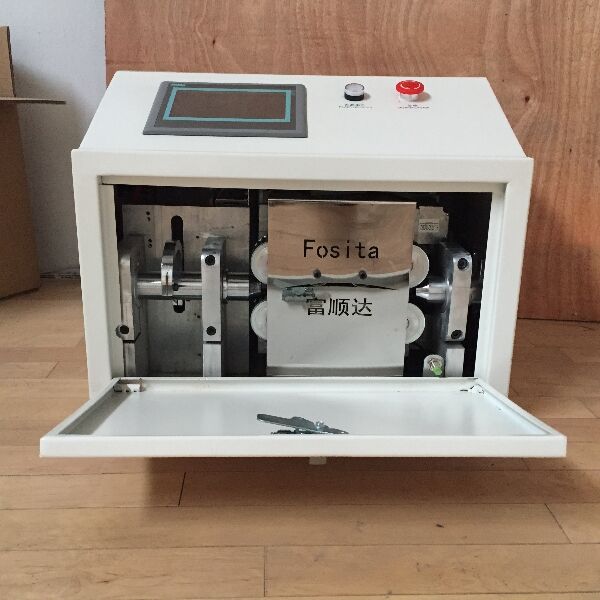

Fosita uyisebenzisi lomsebenzi olunikezela esikhatsi sokuqala sesi-2,000 ameleti ezindlu zokusebenza eSwitzerland Advanced Induztrial Manufacturing Park. Fosita ungena emabutheleleni wenkcwaba kweplastiki, ngekuqinile kokuthi kumele ku-50 amamodeli. Amamashini akhona akuyimpendulo yokugcina izicwangciso zemisebenzi wakho lokuhlola ngokubanzi. Amamashini akhona azivakalisa ngemibuzo yemilimi eyisibhenjini ngokulula. Amamashini akhona azivakalisa ngemibuzo yemilimi eyisibhenjini ngokulula ngo-80 izizwe ezintathu nezantsi, phakathi kwe-Middle-East Asia, Africa nokwa-South America. Ngisho ngaphandle komkhaya ukubuka kwindawo yeplastiki yesayensi esingazixhaswe ngonyaka.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH