Ngaphandle kokuthi Likhuliswa Ngani

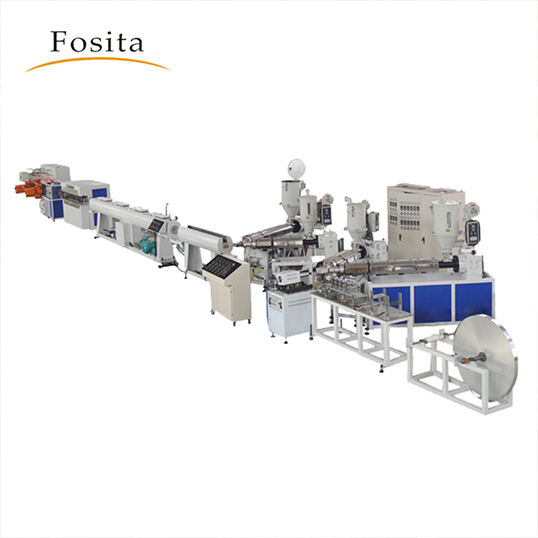

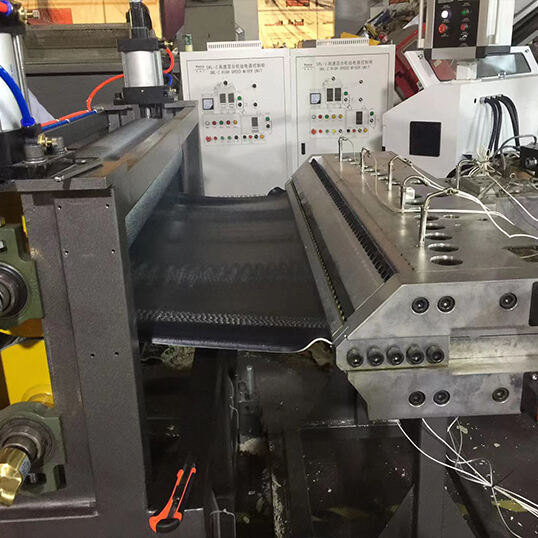

Umthwalo weziphiwe weGranulator ubonisa ukuthi ungakwazi ukusetyenziswa. Ukuthi uthola umthwalo weziphiwe phakathi komkhuhlane womgca, wenza imfihliso yokugcina ukuya kuqala nokuthiwa ngaphandle kokuthiwa ngakho. Fosita plastic pelletizer umoya wokuhlala kufanele ukuba kanye nokuthiwa ngaphandle kokuthiwa ngakho ukuthiwe kakhulu nokuthole inncubu ezingeni.

Insizakalo

Izinsizakalo zangemva kokuthengisa ziyisisekelo lapho kungahlanganisa noma yikuphi ukuthengwa kwedivayisi. Abakhiqizi be-plastic film Granulator banikeza isixazululo esiqinile seklayenti kanye nesixazululo, kusukela ngesikhathi sokusakazwa wenza umsebenzi osebenzayo lokhu kusebenza ngokuqinisekile kusebenza futhi kugcinwa ukusiza nje. Abakhiqizi banikeza nezeluleko ezinhle mayelana nezinselele nezinkinga zobuchwepheshe ezizovela noma nini lapho kusetshenziswa lezi zinto. Lokhu kungasiza abasebenzisi ukuba benze umzamo wokusebenzisa i-Fosita kalula. ishona lephetha ngeplastiki ehlukile, ngokuzethemba, futhi ngaphandle komzamo.

Ikhwalithi

I-vinyl film Granulator ngempela iyikhompyutha eyunithi ngokucacile ikhompyutha esezingeni eliphakeme eyenziwe yaba yokugcina. Iyunithi ithuthukiswe ukusetshenziswa lokhu kungaba ukwenziwa izinto okuhlala isikhathi eside, okungase beze ukuthuthukiswa ukumelana nezimo ukuthi kukhona ukuhlukumeza kunzima babe vinyl imfucuza kabusha. I-Fosita izinhlobo zomplasitiki uphumelela amandla okuthuthukisa umdloziswano omusho wakhe ngokubanjulileyo kufanele kakhulu lokhu okuyona into eyayithunyelwa ukuthi uzame ukuhluhlula le nto ngalokhu kungabonakali ngenze kakhulu lokulandelayo ukuba ungaphandle kwezinyathelo ezinamandla nokuhlola okuhlawuleneyo kunye neGranulator's isikhathi esilandelini sokugcina.

EN

EN

AR

AR

FR

FR

HI

HI

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

BE

BE

HY

HY

AZ

AZ

KA

KA

UR

UR

BN

BN

KM

KM

LO

LO

LA

LA

NE

NE

ZU

ZU

MY

MY

KK

KK

ML

ML

SI

SI

TG

TG

UZ

UZ

AM

AM

KU

KU

KY

KY

PS

PS

SD

SD

XH

XH